How to Find a Reliable Sports Sunglasses Factory in China That Supports OEM/ODM Service

XIAMEN, FUJIAN, CHINA, December 15, 2025 /EINPresswire.com/ -- In an increasingly competitive global marketplace, selecting a trustworthy manufacturing partner for performance eyewear is a critical decision. Companies seeking to launch or expand sports eyewear lines should particularly look for a partner that supports full OEM/ODM service, delivers certified products and offers flexibility in design and branding. Among these sourcing decisions, one standout category is the role of an OEM Prescription Ski Goggles Supplier – a specialized offering that extends standard sports sunglasses into high-value, prescription-capable goggles for winter sports and higher spec applications. These premium eyewear solutions demand precisely controlled optics, strong materials, lens coatings and brand customization—so working with a factory experienced in both sports sunglasses and outdoor eyewear is essential.

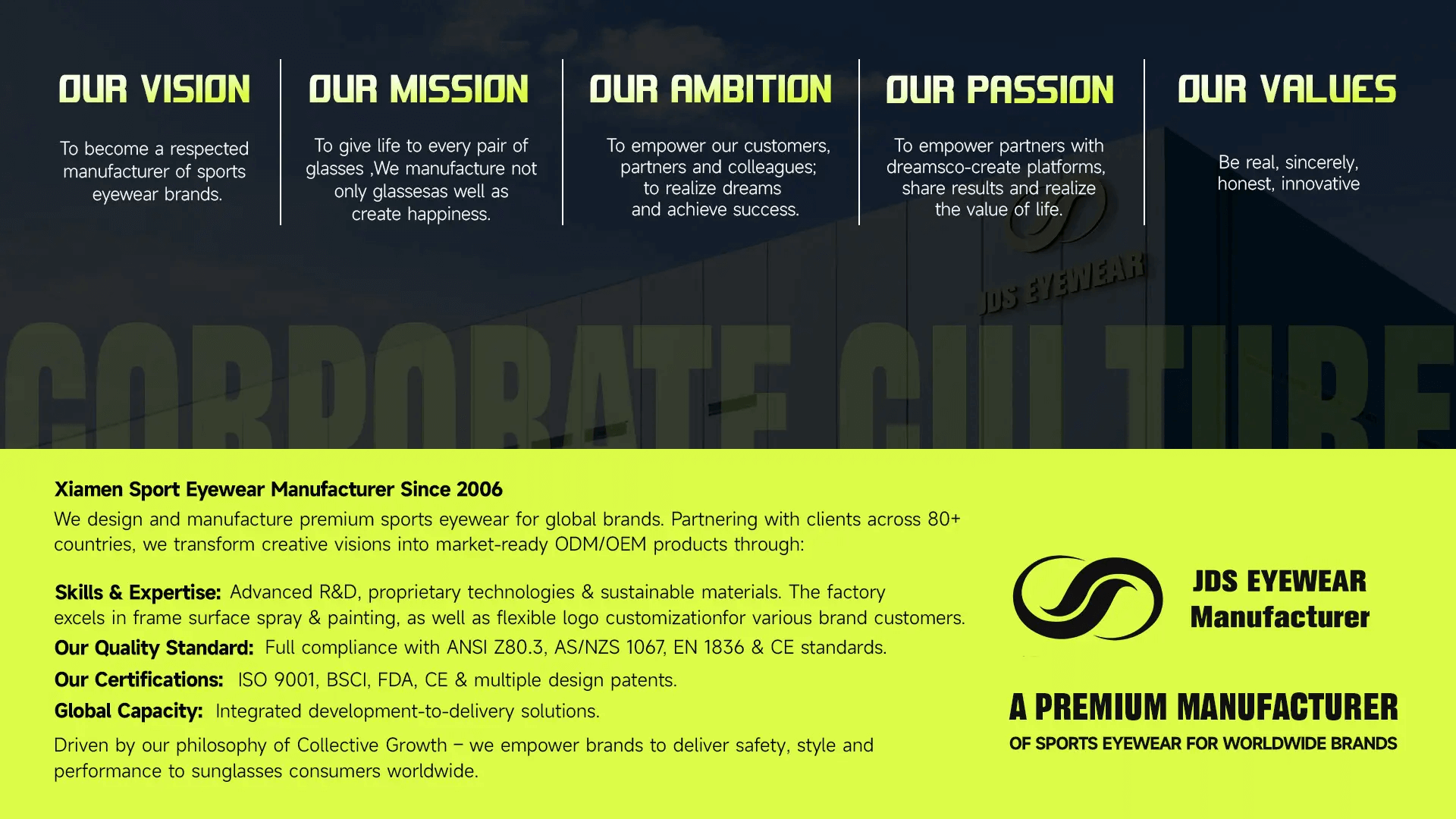

One such factory is JDS Eyewear, a professional manufacturer, supplier and exporter of high-end sunglasses. Founded in 2006, JDS Eyewear focuses on the design and manufacture of sports sunglasses and outdoor sunglasses, serving customers all around the world. With its rich design experience and production capacity, the company works hand-in-hand with clients to develop their own brands and full lines of performance eyewear.

Market Landscape & Trend Insights

The sports and outdoor eyewear industry is poised for significant growth. Market research indicates that the sports sunglasses segment alone is expected to expand from approximately USD 1.31 billion in 2022 to nearly USD 2 billion by 2030, growing at a CAGR of about 5.3%. This broader trend underscores the opportunity for brand owners to source production with capable partners in China.

Why China Makes Sense for Sourcing

China has a well-established eyewear manufacturing ecosystem. Skilled workers, mature supply chains, advanced tooling and proximity to ports contribute to efficient delivery, competitive cost and technical competence. One industry overview notes: "Chinese sunglass factories … offer high quality at lower costs, using advanced machinery and strict quality control." For brands seeking reliable OEM/ODM partners, China remains a key sourcing region.

The Rise of Performance & Customization

Today’s consumer expects more than UV protection—they want gear that performs, integrates with their lifestyle and expresses their identity. Features like UV400 lenses, anti-fog coatings, lightweight TR90 frames, custom branding and sport-specific designs (cycling, running, skiing) are no longer optional. OEM and ODM services enable brands to differentiate—with bespoke logos, customised lens tints, frame colours and packaging.

Supplier Selection: Best Practices

Selecting a reliable factory requires more than just finding the lowest price. Key factors include production capacity, quality systems, certifications, design capabilities, delivery reliability and brand-friendly tooling flexibility. According to sourcing guidance for eyewear: assessing capacity, evaluating material quality and establishing long-term partnerships are essential. Brands that perform these checks are better positioned to avoid delays, quality issues and cost overruns.

Next-Gen Trends: Sustainability & Tech

Growing demand for sustainable materials, recycled plastics and eco-friendly coating processes is reshaping the eyewear industry. In parallel, technological advancements—such as photochromic lenses, integrated heads-up displays (for elite sports) and prescription-capable performance eyewear—are creating new categories. For brands engaging in OEM/ODM partnerships, working with a factory that keeps pace with these innovations is a competitive advantage.

Why JDS Eyewear is a Trusted OEM/ODM Partner

Founded in 2006, JDS Eyewear has built nearly two decades of experience in designing and manufacturing high-end sports and outdoor sunglasses. The company prides itself on offering full OEM/ODM services and supports global brand clients in launching customised eyewear collections.

Core Strengths

Full Service OEM/ODM Support: JDS Eyewear assists clients from conceptual design, mould development, lens/coating selection, to logo placement, packaging and brand integration.

Robust Design & Production Capacity: With a dedicated design team and modern production workshop, JDS offers the flexibility to serve both small and large orders—ideal for brand owners seeking scalable solutions.

Brand-Focused Collaboration: Rather than simply manufacturing, JDS works with clients globally to develop their own brands and unique product lines, leveraging its 2006-established base and design experience.

Certified Quality & Export Readiness: The company underscores its ability to support international markets by adhering to export standards and working with lenses and materials that meet health and safety requirements.

Product Range & Application Scenarios

Sports Sunglasses: For activities like running, cycling, tennis; features include wrap-around frames, UV400 lenses, anti-slip design.

Outdoor & Active Lifestyle Eyewear: Hiking, fishing, travel—design combines durability, style and performance.

Prescription & Performance Goggles: Extending into categories like skiing, winter sports and outdoor adventure, the factory supports customised solutions including prescription capability, mirrored/coated lenses and full-frame protection.

Custom Logo Collections: Brands can source custom-logo full-frame cycling glasses, mirrored lenses, event-specific designs—all manufactured with JDS's OEM/ODM support.

Client Success Stories

Though many client details remain under confidentiality, JDS Eyewear's global reach is clear. Brand clients from North America, Europe, Australia and Asia have benefited from JDS’s end-to-end service—delivering products that combine high performance, distinctive branding and reliable production. One brand, for example, launched a full-frame cycling sunglasses line with custom lens coatings and logo engraving in the space of six months—benefiting from JDS's design, prototyping and manufacturing expertise.

Future-Ready Manufacturing

JDS Eyewear continues to invest in material innovation (e.g., TR90 frames, bio-based plastics), lens technology and sustainability practices—ensuring the factory remains aligned with evolving brand expectations and market demands.

Conclusion

Finding the right sports sunglasses or performance eyewear manufacturer in China requires diligence, clarity of requirements and partnering with a supplier that offers design flexibility, production scale, certifications and OEM/ODM support. In the search for a reliable partner—especially one capable of supporting categories such as prescription ski goggles—choosing a factory like JDS Eyewear provides brands with a full-service, export-ready solution.

For brand owners and retailers looking to launch or expand high-performance eyewear lines with customised design and seamless manufacturing support, visit the official website for more details: https://www.sportsunglassesmanufacturer.com/

One such factory is JDS Eyewear, a professional manufacturer, supplier and exporter of high-end sunglasses. Founded in 2006, JDS Eyewear focuses on the design and manufacture of sports sunglasses and outdoor sunglasses, serving customers all around the world. With its rich design experience and production capacity, the company works hand-in-hand with clients to develop their own brands and full lines of performance eyewear.

Market Landscape & Trend Insights

The sports and outdoor eyewear industry is poised for significant growth. Market research indicates that the sports sunglasses segment alone is expected to expand from approximately USD 1.31 billion in 2022 to nearly USD 2 billion by 2030, growing at a CAGR of about 5.3%. This broader trend underscores the opportunity for brand owners to source production with capable partners in China.

Why China Makes Sense for Sourcing

China has a well-established eyewear manufacturing ecosystem. Skilled workers, mature supply chains, advanced tooling and proximity to ports contribute to efficient delivery, competitive cost and technical competence. One industry overview notes: "Chinese sunglass factories … offer high quality at lower costs, using advanced machinery and strict quality control." For brands seeking reliable OEM/ODM partners, China remains a key sourcing region.

The Rise of Performance & Customization

Today’s consumer expects more than UV protection—they want gear that performs, integrates with their lifestyle and expresses their identity. Features like UV400 lenses, anti-fog coatings, lightweight TR90 frames, custom branding and sport-specific designs (cycling, running, skiing) are no longer optional. OEM and ODM services enable brands to differentiate—with bespoke logos, customised lens tints, frame colours and packaging.

Supplier Selection: Best Practices

Selecting a reliable factory requires more than just finding the lowest price. Key factors include production capacity, quality systems, certifications, design capabilities, delivery reliability and brand-friendly tooling flexibility. According to sourcing guidance for eyewear: assessing capacity, evaluating material quality and establishing long-term partnerships are essential. Brands that perform these checks are better positioned to avoid delays, quality issues and cost overruns.

Next-Gen Trends: Sustainability & Tech

Growing demand for sustainable materials, recycled plastics and eco-friendly coating processes is reshaping the eyewear industry. In parallel, technological advancements—such as photochromic lenses, integrated heads-up displays (for elite sports) and prescription-capable performance eyewear—are creating new categories. For brands engaging in OEM/ODM partnerships, working with a factory that keeps pace with these innovations is a competitive advantage.

Why JDS Eyewear is a Trusted OEM/ODM Partner

Founded in 2006, JDS Eyewear has built nearly two decades of experience in designing and manufacturing high-end sports and outdoor sunglasses. The company prides itself on offering full OEM/ODM services and supports global brand clients in launching customised eyewear collections.

Core Strengths

Full Service OEM/ODM Support: JDS Eyewear assists clients from conceptual design, mould development, lens/coating selection, to logo placement, packaging and brand integration.

Robust Design & Production Capacity: With a dedicated design team and modern production workshop, JDS offers the flexibility to serve both small and large orders—ideal for brand owners seeking scalable solutions.

Brand-Focused Collaboration: Rather than simply manufacturing, JDS works with clients globally to develop their own brands and unique product lines, leveraging its 2006-established base and design experience.

Certified Quality & Export Readiness: The company underscores its ability to support international markets by adhering to export standards and working with lenses and materials that meet health and safety requirements.

Product Range & Application Scenarios

Sports Sunglasses: For activities like running, cycling, tennis; features include wrap-around frames, UV400 lenses, anti-slip design.

Outdoor & Active Lifestyle Eyewear: Hiking, fishing, travel—design combines durability, style and performance.

Prescription & Performance Goggles: Extending into categories like skiing, winter sports and outdoor adventure, the factory supports customised solutions including prescription capability, mirrored/coated lenses and full-frame protection.

Custom Logo Collections: Brands can source custom-logo full-frame cycling glasses, mirrored lenses, event-specific designs—all manufactured with JDS's OEM/ODM support.

Client Success Stories

Though many client details remain under confidentiality, JDS Eyewear's global reach is clear. Brand clients from North America, Europe, Australia and Asia have benefited from JDS’s end-to-end service—delivering products that combine high performance, distinctive branding and reliable production. One brand, for example, launched a full-frame cycling sunglasses line with custom lens coatings and logo engraving in the space of six months—benefiting from JDS's design, prototyping and manufacturing expertise.

Future-Ready Manufacturing

JDS Eyewear continues to invest in material innovation (e.g., TR90 frames, bio-based plastics), lens technology and sustainability practices—ensuring the factory remains aligned with evolving brand expectations and market demands.

Conclusion

Finding the right sports sunglasses or performance eyewear manufacturer in China requires diligence, clarity of requirements and partnering with a supplier that offers design flexibility, production scale, certifications and OEM/ODM support. In the search for a reliable partner—especially one capable of supporting categories such as prescription ski goggles—choosing a factory like JDS Eyewear provides brands with a full-service, export-ready solution.

For brand owners and retailers looking to launch or expand high-performance eyewear lines with customised design and seamless manufacturing support, visit the official website for more details: https://www.sportsunglassesmanufacturer.com/

Xiamen Jiadesheng Eyewear Co., Ltd.

Xiamen Jiadesheng Eyewear Co., Ltd.

+86 18850589137

info@jdseyewear.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.